An engineer in the making: Max Leabman (’25) builds 3D printers

Max Leabman (’25) builds 3D printers to foster his passion for engineering, while creating products that benefit his local community.

Max Leabman (‘25) has been fascinated by engineering since he was a toddler. He displays his passion by building and designing his own 3D printers. For him, aspects of engineering, such as additive manufacturing, are key to the future of technology and industry.

“This started at the beginning of quarantine in May 2020. I decided to pull the trigger on a 3D printer because I was bored, and I’d wanted one for the past couple of years. Over the summer, I took it up to my grandparents’ house, and I heavily modified it,” said Leabman.

Creating a Goal

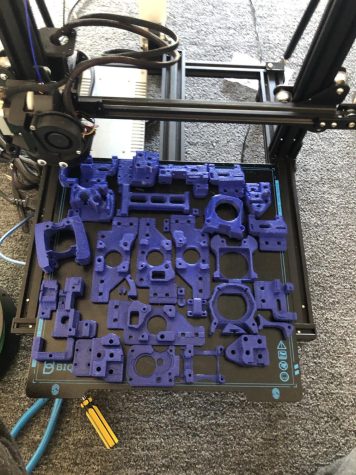

Leabman built his first machine using a kit, but by the second time around, he wanted to try something new. Completing his first project gave him a new motivation, and Leabman was intent on creating something completely his own.

“I actually built my own machine. And this was completely different because I built it from scratch with a lot of parts that I designed myself. It was really hard, but also really easy and fun at the same time. The second machine I built was a lot faster. And then this new machine, I’m not just pulling everything from open source this time. It’s designed entirely by me except for parts that I’ve actually pulled from online,” said Leabman.

Between quarantine and constructing a 3D printer for the first time, Leabman was not exempt from any obstacles. Through these setbacks, he has improved his techniques and learned from his mistakes.

“The first and second machine, I had supply problems. I wasn’t able to get all the parts I needed, and I shorted out a couple of boards. At least old me was extremely clumsy. So I blew, I think, two or three boards in one year. And that’s certainly not fun because I would have had my first printer assembled in just like a week or two,” said Leabman.

Leabman can use his printers to design new inventions or solve small problems in daily life. For instance, he has created a 3D-printed lightning bolt piece that holds open the door of an H-building classroom. Using his first printer, he has made another, and he plans to finish constructing a third printer by late 2023.

“Those are the biggest projects I’ve made. But it always is fun designing stuff for family, friends, and the golf team. And people at school need my help,” said Leabman.

Dreaming Big

Leabman’s ambitions extend past his printers. He has greater goals not only for his high school career but also for his life after college.

“I think towards the end of high school, I might try to release a product, whether it’s the printer, swing trainer, or something else. And then once I’m out of college, I’ll definitely try to build a brand based on additive manufacturing and what I consider as the next generation of engineering, which is producing a much larger variety of different types of products and using this technology,” said Leabman.

Building and designing 3D printers is no small feat. This project helps Leabman develop a myriad of skills, from construction to problem-solving. He plans to take these skills into more extensive projects, starting his career.

“I’m trying to use this as a way to get into engineering. I’ve done engineering before, but not on this type of scale, and I feel like doing these types of projects will give me the knowledge and also the capability to do other stuff,” said Leabman.

Your donation will support the student journalists in the AVJournalism program. Your contribution will allow us to purchase equipment and cover our annual website hosting costs.